NUL student turns maize cobs into paper innovation

SHARE THIS PAGE!

In a groundbreaking initiative blending sustainability and innovation, Moeketsi Shale, a student of Chemical Technology at the National University of Lesotho (NUL) has developed a method to convert discarded maize cobs into usable paper.

In partnership with Molhen Paper Solutions, a local paper bag manufacturing company, Shale’s project seeks to offer a low-cost, eco-friendly alternative to imported paper and plastic packaging in Lesotho.

What was once treated as agricultural waste – maize cobs left behind after harvest – is now being transformed into a promising resource for the country’s packaging industry.

The project, supported by the NUL Innovation Hub, aims to advance Lesotho’s transition to sustainable production by using locally available materials.

“Maize cobs are abundant after the harvest season and are typically discarded. However, they contain cellulose, the primary component of paper. This inspired me to investigate their potential as a raw material for paper production,” said Shale in an interview with theReporter.

Under the supervision of Seliee Thabane, Shale designed a process that involves several cost-effective and scalable steps. The maize cobs are first collected, cleaned to remove impurities, then chopped into smaller pieces and oven-dried to eliminate moisture. These fragments are then milled into a fine powder, which undergoes a pulping process using hot water and specific chemicals to extract cellulose fibres.

To improve the aesthetic and commercial quality of the final product, the cellulose is bleached to enhance its brightness. The pulp is then spread onto mesh frames and pressed into sheets, resulting in a smooth, flexible, and durable paper suitable for various packaging uses.

The potential benefits of this innovation are far-reaching. By utilising maize cobs, Lesotho could reduce its reliance on wood-based paper imports, conserve forests, and cut down on pollution from transport and plastic waste.

“This initiative promotes a circular economy. Instead of burning or discarding maize cobs, we are repurposing them into useful paper products. This benefits businesses, the environment, and Lesotho as a whole,” Shale explained.

He also explored blending hemp fibres with the maize cob pulp. Known for its strength and fast growth, hemp could further enhance the durability and versatility of the resulting paper, making it suitable for products like gift bags, office stationery, and biodegradable food packaging.

To ensure the process could be adopted by small-scale manufacturers, Shale carefully documented each phase (from cleaning the cobs to drying the finished paper sheets) with an emphasis on affordability, simplicity, and safety. His research demonstrated that agricultural waste could serve as a viable, high-quality alternative to traditional wood pulp, using only basic equipment and readily available chemicals.

Nonetheless, challenges arose, particularly during the bleaching stage. Shale had to carefully calibrate chemical use to achieve the desired whiteness without weakening the fibres. Too much bleaching compromised paper strength, while too little left the product discoloured. After thorough experimentation, he was able to strike an effective balance.

Unlike plastic bags that persist in the environment for centuries, maize cob paper is fully biodegradable, offering a clean, environmentally conscious option for consumers and companies looking to reduce their plastic footprint.

If implemented successfully, the innovation could significantly impact Lesotho’s economy. The country currently imports much of its packaging material; this has proved to be an expensive and unsustainable practice. Producing paper bags locally from agricultural waste could reduce costs, create employment, limit waste, and spark rural industry development.

Shale’s work exemplifies how academic research, when paired with community partnerships and local materials, can fuel sustainable development and home-grown solutions to national challenges.

New border plan to advance regional trade

7 days ago

Foul language lands man in court

7 days ago

Youth demand action on unemployment

7 days ago

Ex-ministers threaten to sue govt

7 days ago

CBL launches LERIMA awareness campaign

7 days ago

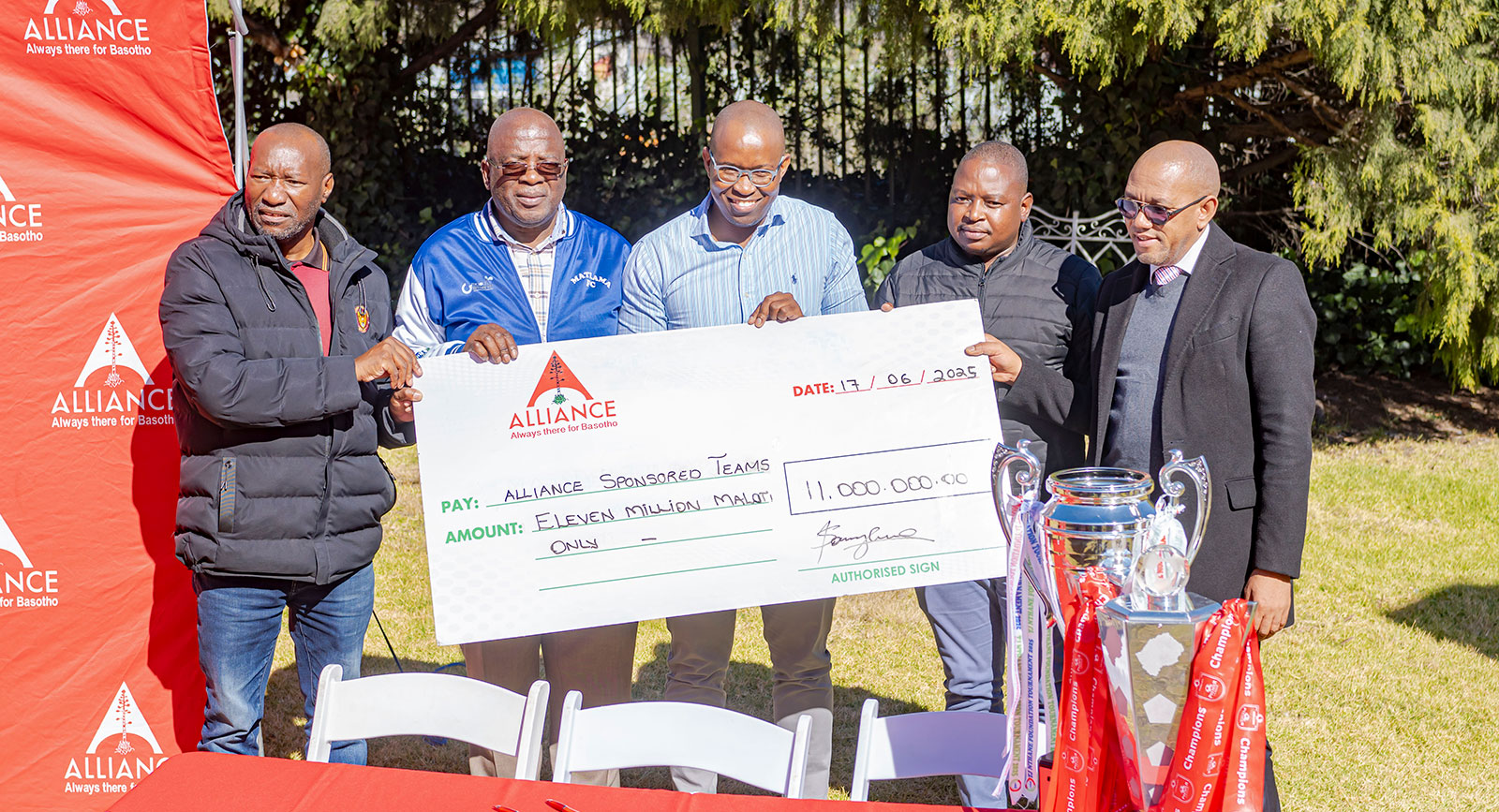

Alliance extends deal with premier league teams

10 days ago